Saturday, August 2nd, I spent a few hours on the sailing dinghy shaping the starboard aft thwart, among other various duties. To begin with, I water washed all of the epoxy fill applied to the old rail fastener holes - using water and a scotch-bright pad. Following the water washing to remove the amine blush from the cured epoxy, I used a 5" finish sander and 80-grit pads to rough-fair the surfaces. Prior to priming the hull (Alexseal primer and topcoat paints arrived Friday evening), I will sand the hull with 80 and 120 grits. The following few photos are referencing the filled and rough-sanded fastener holes.

Port

Starboard

Starboard, looking aft

Port, aft quarter

The real focus of today was completion of the starboard aft thwart - shown below in the "roughed-in" phase. Using 5/4 teak, I applied the previously constructed template and replicated it onto the wood. A quick couple passes on the bandsaw, and I was test-fitting the thwart in its future home. Again, taking the angle off the stern, I removed a sliver from its aft portion and then began shaping the balance of the thwart by hand. Finally, I achieved a nice "roughed-in" fit. I will eventually make some minor alterations to achieve best fit, but for now I had accomplished what I intended for the day.

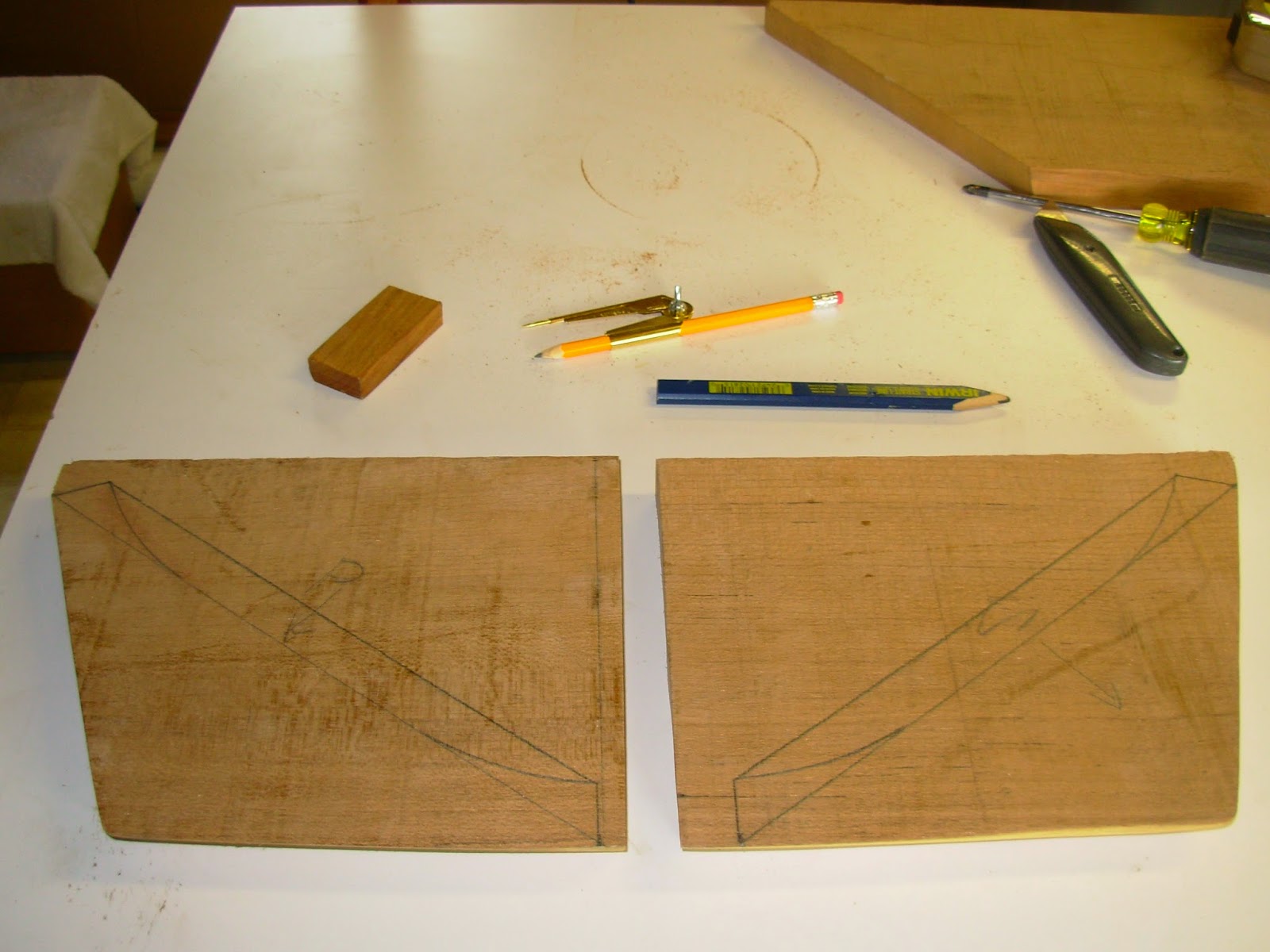

Back in the shop, I made various markings on the port and starboard thwarts to begin the process of laying out the final shape. Not wanting to nullify hours of work, I began laying out and removing material with the bandsaw in most deliberate way. I had a general idea of their final appearance, but did not want to be hasty in removing material should I have a last minute change of heart.

Below, the port and starboard aft thwarts coming close to their final shaping. The amount of material will provide great stability along the boat's sheer, and provide a bit of surface area for the captain, or first mate, to rest a hand or an arm.

Port aft thwart.

Starboard aft thwart.

Total Time: 3.5 hrs

No comments:

Post a Comment